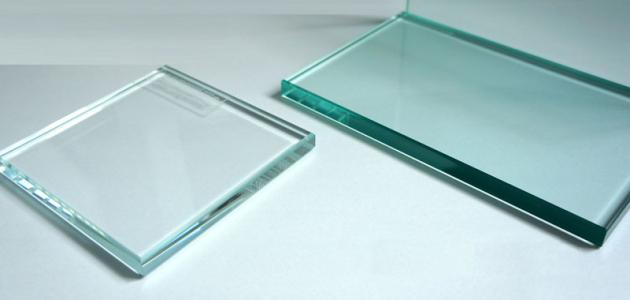

the glass

Man has made glass for thousands of years, as many historical manuscripts were found that confirmed the existence of glass tools that ancient humans had been using for more than two thousand years BC, such as: decorative pieces, household glassware, and ornamental pieces. Then man evolved to introduce glass into the field of industry and buildings. Such as doors, windows, and glass facades. In this article, we will talk about how glass is made.

Glass components

- Sand or silica: Silicon acid is the main component used in the manufacture of ordinary glass, and sand is the source of obtaining it. It is not preferable to use quartz sand, and it must be taken into account that the sand contains 80% of silicon oxide, and a few impurities, especially colored ones.

- Sodium compounds: It reduces the melting point of glass and plays a major role in its formation.

- Lime or dolomite: The glass gains the hardness it needs; Because it contains calcium oxide.

- Feldspar: It is easy to melt and is cheap.

- Borax: It consists of boron and sodium, which reduce the coefficient of expansion of glass, making it melt quickly. Therefore, glass that contains a high percentage of boron is of good quality and does not break if it is suddenly cold or hot.

- Colourants or enhancers: Coloring materials and enhancers help improve the quality of glass, such as: titanium oxide, lead oxide, and barium oxide.

How is glass made?

Dissolving

Special furnaces are used to melt and melt glass, such as: the basin furnace, or the jar furnace, and they facilitate the process of melting the components that go into making the glass so that they are later transformed into light materials in order to prepare for the forming stage, where the materials used are melted after obtaining them as powder or granules that are mixed in specific quantities. Then put it in the oven.

Read also:How to make a fanformation

After melting the glass is cooled to the point where it can be shaped, then the glass forming stage begins, where more than one technique is used to shape the glass, such as: blowing, automatic shaping, and manual shaping. This stage must be implemented quickly before the glass turns from a paste state to solid state.

Cooling

A special oven is used for cooling or tempering, and it is set at a temperature ranging between 400-600. This stage can be carried out slowly, as the glass may be exposed to breakage, cracking, or irregular structure when cooled quickly, resulting in Weak areas appear in the glass pieces, and the glass continues to cool until the shape of the glass pieces stabilizes.

Read also:How to make a fish tank ornamentTermination

The glass is polished and cleaned after it has completely cooled, after which the glass is ready for use.